Tomorrow is New Year’s Day. No commitments, have lots of time of knit, looking forward to doing the first project of the year and the forecast high for Thursday is 10 degrees. It’s a perfect time to whip up a pair of leg warmers. These were knit flat on a Brother KH860 with KR850 ribber using Franklin Sock Yarn from Valley Yarns.

Gauge

Stockinette: 31 stitches x 40 rows = 4″/10cm

Finished Size:

Ankle: 7 1/2″

Cuff: 10 1/2″

Total Length: 14″

Cast On

Disconnect ribber carriage and position it on the left.

Position main carriage with ribber arm on the right.

Set pitch lever to H and rack to position 5.

Set up for industrial rib with edge pairs on the main bed (see note 1): 36L – 35R on the main bed, 35L – 33R on the ribber. Pull one extra ribber needle (35R) to WP to round off the zig-zag row.

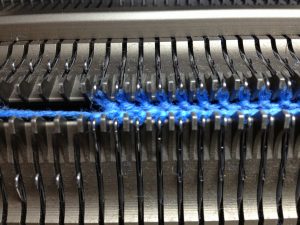

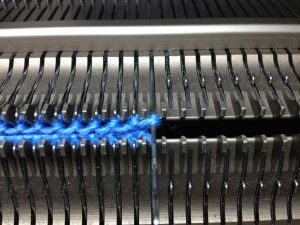

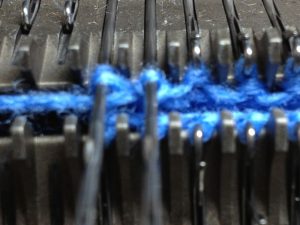

Pull ribber needles a little higher than WP and make sure all latches are open. The tips of the ribber needles should be even with the main bed’s gate posts. Main bed needles should be in WP.

Thread the main carriage leaving long tail for seam, set the tension to T0 and RC = 0.

Rack to position 6. Knit from right to left with the main carriage only.

Carefully push the ribber needles back to WP. Make sure the floats that passed over the ribber needles are caught in the needle hooks.

Hang the ribber comb and weights (see note 2).

Connect the ribber carriage and set the carriages to knit circular: depress the left part button on the main carriage and set the ribber’s right cam lever to PR.

Set the tension on both carriages to T1. Knit 2 rows, ending COL RC=3.

Transfer the extra ribber stitch on 35R to 34R on the main bed.

Set the tension on both carriages to T2. Knit 1 more row, ending COR RC = 4.

Ribbed Ankle

Set both carriages to knit: release the part button on the main carriage and set the ribber’s right cam lever to N).

Set the tension on both carriages to T5.

Rack to position 5.

Knit 21 rows, ending COL RC = 25.

Transfer the left stitch of each pair of ribber stitches to the corresponding empty main bed needle (see note 3).

Knit 1 row, ending COR RC = 26.

Set pitch lever to P.

Transfer the remaining stitches from the ribber to the corresponding needle on the main bed. There will be two stitches on these needles.

Leg

Drop ribber bed, remove ribber arm and attach normal sinker plate.

Set RC = 0.

Knit 1 row.

* Increase 1 stitch each side.

Knit 4 rows.

Increase 1 stitch each side.

Knit 5 rows. **

Repeat from * to ** 10 more times RC = 100 (58L – 57R).

Increase 1 stitch each side (59L – 58R).

Knit 1 rows RC = 101.

Ribbed Cuff

Set pitch lever to P and rack to position 5.

Transfer pairs of stitches from main bed to ribber for industrial rib 59L – 57R (see note 4). On right hand side, put two stitches on 56R and edge stitch on 57R. On main bed, there will be one stitch every 3rd needle from 57L – 55R.

Transfer heel of each main bed stitch right one needle needle to complete industrial rib setup.

Set pitch lever to H.

Set RC = 0.

Knit 44 rows and bind off.

Finishing

With right side facing, seam ankle rib and leg.

Turn inside out and continue seaming cuff.

Notes

- Placing the edge stitches on the main bed means there will be one knit stitch on either side of the ankle seam.

- On my Brother, the two beds are close enough that getting the ribber comb and thick industrial rib to hang freely is problematic. I get around that issue by pulling up on the bracket levers and pushing down on the ribber bed to position it slightly lower than normal.

- I find that transferring both stitches from the ribber to the main bed at the same time creates a little bump on the inside of the knit that I don’t like. Transferring half the stitches on one row and the other half on a separate row eliminates the bump.

- Similar to the ankle rib, placing the edge stitches on the ribber means there will be one knit stitch on either side of the cuff seam. This is a turn-down cuff, so the side facing is the side that will be showing.

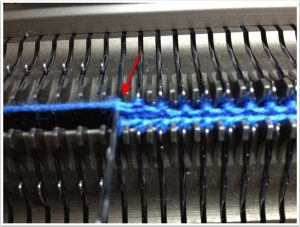

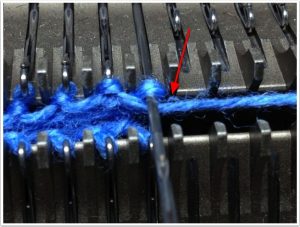

After knitting the last circular row, pull the edge needle next to the carriage to hold. See how the yarn running from the carriage runs underneath the needle? This will manually wrap the needle when we knit across.

After knitting the last circular row, pull the edge needle next to the carriage to hold. See how the yarn running from the carriage runs underneath the needle? This will manually wrap the needle when we knit across. Now knit across. Notice how the yarn travelled from the non-heel bed and floats across the held needle. That’s the thread that will connect the last circular row to the first row of your short rows on this side.

Now knit across. Notice how the yarn travelled from the non-heel bed and floats across the held needle. That’s the thread that will connect the last circular row to the first row of your short rows on this side. The carriage is now on the right side.

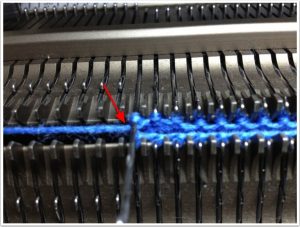

The carriage is now on the right side. Pull the needle next to the carriage to hold…

Pull the needle next to the carriage to hold… … and knit across. You now have two needles in hold — one on each side. You’ve done two carriage passes and the carriage is back at the side where you started your short rows. For me, that’s on the left.

… and knit across. You now have two needles in hold — one on each side. You’ve done two carriage passes and the carriage is back at the side where you started your short rows. For me, that’s on the left. On the carriage side, notice how the thread from the carriage is laying on top of the edge needle. We want to manually wrap the edge needle a second time, so grab that thread…

On the carriage side, notice how the thread from the carriage is laying on top of the edge needle. We want to manually wrap the edge needle a second time, so grab that thread… … and move it underneath the edge needle so it will manually wrap the needle on the next carriage pass.

… and move it underneath the edge needle so it will manually wrap the needle on the next carriage pass. Pull one more needle on the carriage side to hold…

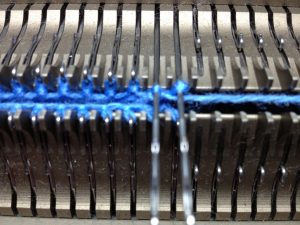

Pull one more needle on the carriage side to hold… … and knit across. See how the yarn is now floating over the two edge needles. Yes, it looks strange, but ignore it. This is exactly what you want.

… and knit across. See how the yarn is now floating over the two edge needles. Yes, it looks strange, but ignore it. This is exactly what you want. Now do the same for the other side. Move the yarn underneath the edge needle…

Now do the same for the other side. Move the yarn underneath the edge needle… … pull another needle to hold and knit across.

… pull another needle to hold and knit across.